- Home Page

- Company Profile

-

Our Products

- CPC Linear Motion Guide

- ARC Series: Standard 4-row ball bearing guides.

- MR Series: Miniature linear guides with stainless steel construction.

- LRR Series: Low-profile roller bearing guides

- MRU Series: Miniature linear guides with bottom-mounting options

- HRU Series: High-rigidity 4-row ball bearing guides with U-shaped rails

- ARU Series: Standard 4-row ball bearing guides with U-shaped rails.

- ERC Series: Low profile 4-row ball bearing guides

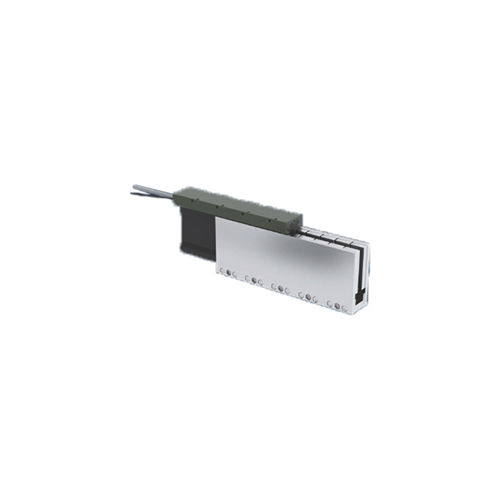

- Ironless Servo Motor Linear Motion Guideway

- WRC Series 4 Row Wide Ball Type Linear Motion Guideway

- HRR 4 Row Type Linear Motion Guideway

- HRR Series Standard Roller Linear Motion Guideway

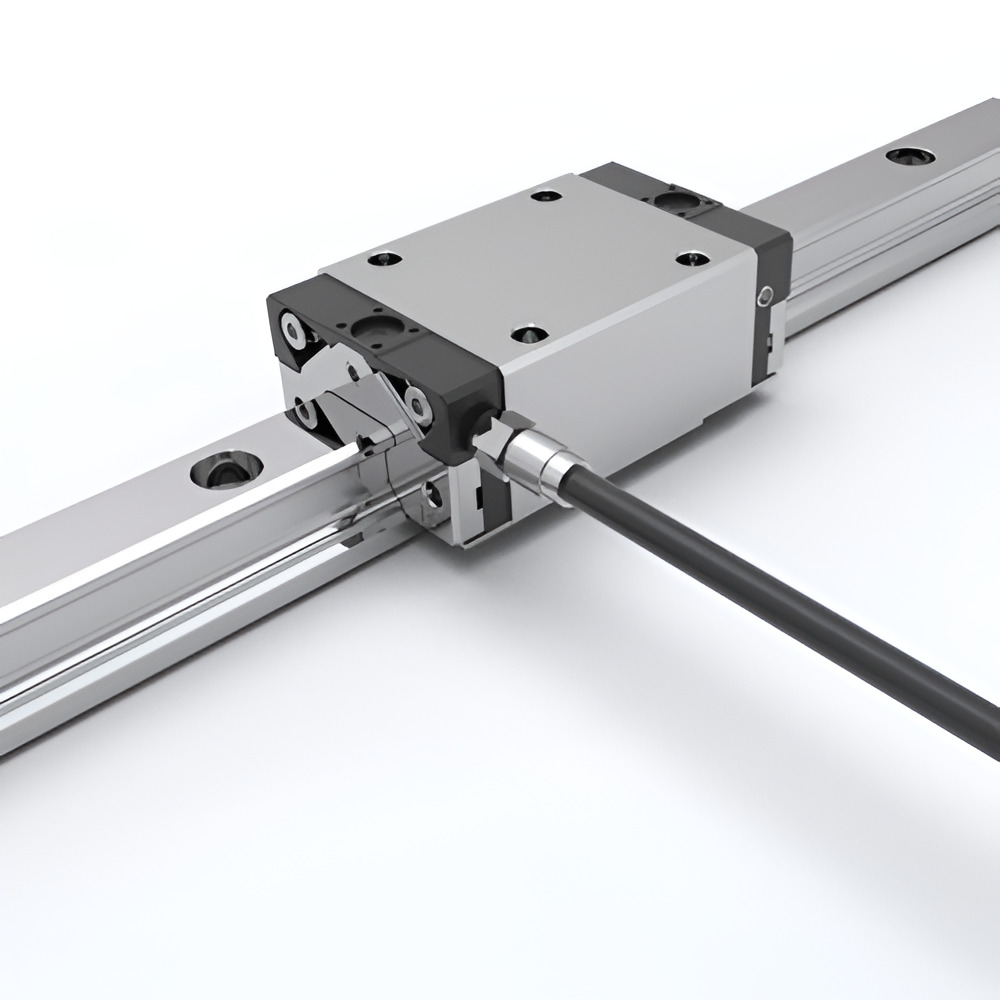

- MSS Series Linear Motion Guideway With Magnetic Encoder

- ARR 4 Roller Type Linear Motion Guideway

- 15-55 Roller Linear Motion Guideway

- HRC Series: High-rigidity 4-row ball bearing guides.

- HRR Series: High-rigidity roller bearing guides.

- ARR Series: Standard roller bearing guides.

- CPC Linear Motor

- Ironless Linear Motor

- UF - Linear Motor Stage

- Motor Servo Drive

- Sensor series

- CLS - Compact Linear Motor Stage

- CLMS - Compact Linear Motor Stage

- MMLS - Moving magnet stage

- Ironcore Linear Motor

- DD Motor

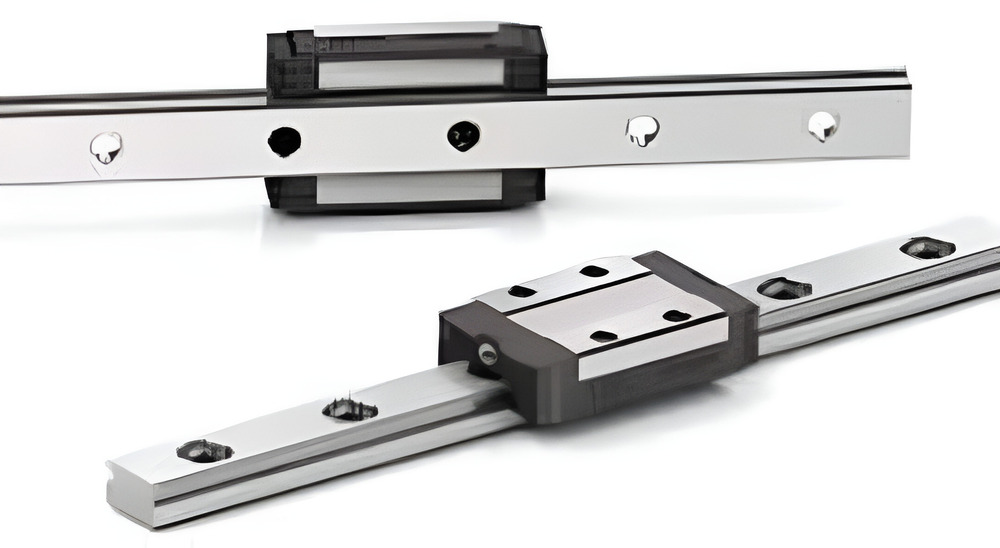

- Standard 4-Row Ball Bearing Linear Guide

- Wide 4-Row Ball Bearing Linear Guide

- Standard 4-Row Roller-type Linear Guide

- ARD Standard 4-Row Ball Bearing Linear Guide

- Miniature Linear Guide

- ST Miniature Stroke Slide Series

- Cross Roller Series

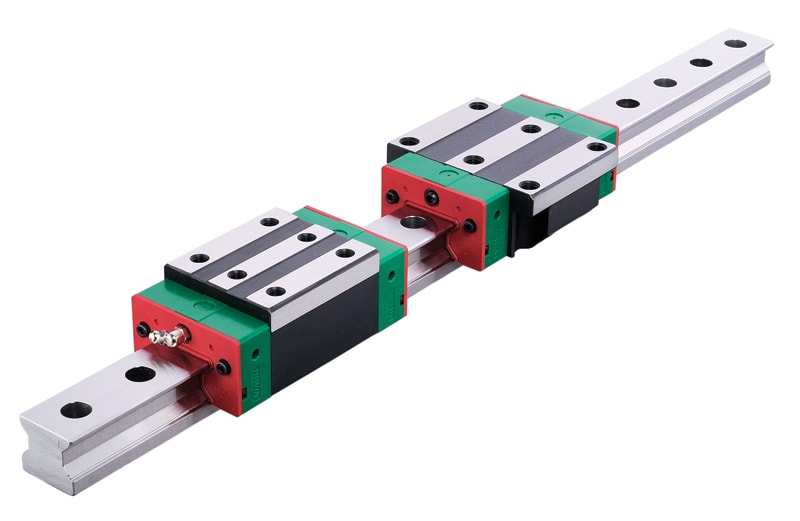

- Hiwin Linear Guide

- CPC Studio

- CPC Robot

- THK Linear Guide

- THK HSR LINEAR GUIDE

- THK HSR15C LINEAR GUIDE

- THK HSR15LC LINEAR GUIDE

- THK HSR20C LINEAR GUIDE

- THK HSR25LC LINEAR GUIDE

- THK HSR25C LINEAR GUIDE

- THK HSR 20LC LINEAR GUIDE

- THK HSR30LC LINEAR GUIDE

- THK HSR 30C LINEAR GUIDE

- THK HSR35C LINEAR GUIDE

- THK HSR35LC LINEAR GUIDE

- THK HSR45C LINEAR GUIDE

- THK HSR45LC LINEAR GUIDE

- THK HSR55C LINEAR GUIDE

- THK HSR55LC LINEAR GUIDE

- THK HSR65XC LINEAR GUIDE

- THK HSR65XLC LINEAR GUIDE

- THK HSR45LR LINEAR GUIDE

- THK HSR 55R LINEAR GUIDE

- THK HSR 55LR LINEAR GUIDE

- THK HSR65R LINEAR GUIDE

- THK HSR 85R LINEAR GUIDE

- THK HSR 85LR LINEAR GUIDE

- THK HSR35LR LINEAR GUIDE

- THK HSR45R LINEAR GUIDE

- THK HSR35R LINEAR GUIDE

- THK HSR30LR LINEAR GUIDE

- THK HSR30R LINEAR GUIDE

- THK HSR25LR LINEAR GUIDE

- THK HSR25R LINEAR GUIDE

- THK HSR 20LR LINEAR GUIDE

- THK HSR20R LINEAR GUIDE

- THK HSR15LR LINEAR GUIDE

- THK HSR15R LINEAR GUIDE

- THK HSR 65LR LINEAR GUIDE

- HRC Cpc Linear Guide

- HRC15MN - 4-Row ball bearing guides

- HRC35MN - High rigidity 4-Row ball bearing guides

- HRC25ML -High rigidity 4-Row ball bearing guides

- HRC25FN -High rigidity 4-Row ball bearing guides

- HRC25FL -High rigidity 4-Row ball bearing guides

- HRC45FL-High Rigidity 4-Row Ball Bearing Guides

- HRC35MN - High Rigidity 4-Row Ball Bearing Guides

- HRC35ML - High Rigidity 4-Row Ball Bearing Guides

- HRC 35MN High rigidity 4-Row ball bearing guides

- HRC30FN- High rigidity 4-Row ball bearing guides

- HRC30MN High rigidity 4-Row ball bearing guides

- HRC15MN- Ball Bearing Linear Guideway HRC15MN

- HRC20MN - 4-Row ball bearing guides

- HRC - STANDARD 4-ROW BALL BEARING LINEAR GUIDE

- HRC15MN - High rigidity 4-Row ball bearing guides

- HRC20MN - High Rigidity 4-row Ball Bearing Guides

- HRC25MN -High Rigidity 4-row Ball Bearing Guides

- HRC30MN- High rigidity 4-Row ball bearing guides

- HRC30FL- High Rigidity 4-Row Ball Bearing Guides

- HRC35FL - High Rigidity 4-Row Ball Bearing Guides

- HRC15FN -High rigidity 4-Row ball bearing guides

- HRC15FN - High rigidity 4-Row ball bearing guides

- HRC20FN - High Rigidity LM GUIDE

- HRC45FN - High rigidity 4-Row ball bearing guides

- HRC45FN- High rigidity 4-Row ball bearing guides

- HRC15ML -Row ball bearing guides

- HRC30ML - High Rigidity 4-row Ball Bearing Guides

- HRC15FS - High rigidity 4-Row ball bearing guides

- HIWIN HG-SERIES Linear Guideway

- HIWIN- HGH30CA Linear Guide

- HIWIN- HGH35HA Linear Guide

- HIWIN- HGH65CA Linear Guide

- HIWIN- HGH25CA Linear Guide

- HIWIN- HGH45HA Linear Guide

- HIWIN- HGH55HA Linear Guide

- HIWIN-HGH20CA Linear Guide

- HIWIN- HGH45CA Linear Guide

- HIWIN- HGH25HA Linear Guide

- HIWIN-HGH20HA Linear Guide

- HIWIN- HGH30HA Linear Guide

- HIWIN- HGH35CA Linear Guide

- HIWIN- HGW45CC Linear Guide

- HIWIN- HGW65HC Linear Guide

- HIWIN- HGW25CC Linear Guide

- HIWIN- HGW20CC Linear Guide

- HIWIN- HGW20HC Linear Guide

- HIWIN- HGW55CC Linear Guide

- HIWIN- HGW25HC Linear Guide

- HIWIN- HGW55HC Linear Guide

- HIWIN- HGW45HC Linear Guide

- HIWIN- HGW30CC Linear Guide

- HIWIN- HGW35HC Linear Guide

- HIWIN- HGW65CC Linear Guide

- HIWIN- HGW35CC Linear Guide

- HIWIN- HGW15CC Linear Guide

- HIWIN-HGH15CA Linear Guide

- HIWIN -HGW30CA Linear Guide

- THK HRX LINEAR GUIDE

- THK HRX 25C LINEAR GUIDE

- THK HRX 25LC LINEAR GUIDE

- THK HRX 30C LINEAR GUIDE

- THK HRX 30LC LINEAR GUIDE

- THK HRX 35C LINEAR GUIDE

- THK HRX 35LC LINEAR GUIDE

- THK HRX 45C LINEAR GUIDE

- THK HRX 45LC LINEAR GUIDE

- THK HRX 55C LINEAR GUIDE

- THK HRX 55LC LINEAR GUIDE

- THK HRX 65C LINEAR GUIDE

- THK HRX 65LC LINEAR GUIDE

- THK HRX 25R LINEAR GUIDE

- THK HRX 25LR LINEAR GUIDE

- THK HRX 30R LINEAR GUIDE

- THK HRX 35R LINEAR GUIDE

- THK HSR 35LR LINEAR GUIDE

- THK HSR 45LR LINEAR GUIDE

- THK HRX 45R LINEAR GUIDE

- THK HRX 45LR LINEAR GUIDE

- THK HRX 55R LINEAR GUIDE

- THK HRX 55LR LINEAR GUIDE

- THK HRX 65LR LINEAR GUIDE

- THK HRX 65R LINEAR GUIDE

- THK HRX 30LR LINEAR GUIDE

- Hiwin EG-Series

- EGW25CC -Low Profile Ball Type Linear Guideway

- EGH30SA Linear Guideway

- EGH30CA Linear Guideway

- EGH35HA --Low Profile Ball Type Linear Guideway

- EGH15CA -Low Profile Ball Type Linear Guideway

- HIWIN- EGW35CA Linear Guideway

- HIWIN- EGW20SA Linear Guideway

- HIWIN- EGH35CA Linear Guideway

- HIWIN- EGW30CA Linear Guideway

- HIWIN- EGW35SA Linear Guideway

- HIWIN- EGW30SA Linear Guideway

- HIWIN- EGW25SA Linear Guideway

- HIWIN- EGW25SA Linear Guideway

- HIWIN- EGW15CA Linear Guideway

- HIWIN- EGH35SA Linear Guideway

- HIWIN- EGW20CA Linear Guideway

- HIWIN- EGH25CA Linear Guideway

- HIWIN- EGW15SA Linear Guideway

- HIWIN- EGH20CA Linear Guideway

- HIWIN- EGH30SA Linear Guideway

- HIWIN- EGH30CA Linear Guideway

- HIWIN- EGH20SA Linear Guideway

- HIWIN- EGH25SA Linear Guideway

- HIWIN- EGH15SA Linear Guideway

- HIWIN- EGW25CA Linear Guideway

- Hiwin QE-Series Linear Guideway

- QEW15CA Linear Guideway

- QEH15CA - Low Profile Linear Guideway

- QEH25CA Linear Guideway

- QEW30CA Low Profile Linear Guideway

- QEW30SA Low Profile Linear Guideway

- QEH20SA Linear Guideway

- QEW25CA Low Profile Linear Guideway

- QEW20SA Linear Guideway

- QEW15SA Linear Guideway

- QEW35CA Linear Guideway

- QEH20CA - Low Profile Linear Guideway

- QEH15HA Linear Guideway

- HIWIN QEH25SA Linear Guideway

- HIWIN QEW25SA Linear Guideway

- HIWIN QEH15SA Linear Guideway

- HIWIN QEH30SA Linear Guideway

- HIWIN QEH30CA Linear Guideway

- HIWIN QEH35CA Linear Guideway

- HIWIN QEH35SA Linear Guideway

- HIWIN QEW20CA Linear Guideway

- HIWIN QEW35SA Linear Guideway

- CPC Linear Motion Guide

- Contact Us

Standard Roller Linear Motion Guideway

Price 990.0 INR/ Number

Standard Roller Linear Motion Guideway Specification

- Seals Type

- Sealed

- Structure

- Smooth

- Usage

- Industrial

- Material

- Stainless Steel

- Size

- Different available

- Product Type

- Linear Motion Guideway

- Warranty

- 1 YEAR

- Color

- Silver

Standard Roller Linear Motion Guideway Trade Information

- Minimum Order Quantity

- 10 Number

- Supply Ability

- 5000 Per Month

- Delivery Time

- 1 Days

- Main Domestic Market

- All India

About Standard Roller Linear Motion Guideway

Design & Structure

Uses cylindrical rollers (instead of balls), creating line contact which significantly boosts load capacity and rigidity, especially under heavy loads

Typically features four-row, 45 DB contact angles, ensuring equal load handling in radial, reverse-radial, and lateral directions

Includes roller synchronizer mechanisms to reduce internal friction (gear effect), ensuring smoother, quieter movement

Materials & Sealing

Rails and blocks are made from hardened steel or stainless steel, often with corrosion-resistant coatings

Commonly delivered in sealed configurations to keep out debris and preserve lubrication .

Sizes & Ranges

Available in standard sizes like LMR15, LMR20, LMR25, LMR30, LMR35, LMR45, LMR55with some brands offering even up to LMR65

Rails can be manufactured in varying lengths some exceed 6m, depending on supplier

Performance Characteristics

Designed for ultra-high rigidity and super-heavy load applications

Excellent smooth motion, with low friction and noise, high precision, and long lifespan

Ideal for high-end CNC machines, robotics, heavy gantries, and vibration-intensive environments

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in CPC Linear Motion Guide Category

Ironless Servo Motor Linear Motion Guideway

Minimum Order Quantity : 10 Units

Usage : Industrial

Material : Stainless Steel

Structure : Ironless Core Linear Motor with Guide

Size : Different available

HRC Series: High-rigidity 4-row ball bearing guides.

Price 900 INR / Number

Minimum Order Quantity : 1 Number

Usage : Industrial

Material : Stainless Steel

Structure : Smooth

Size : Standard Sizes

MR Series: Miniature linear guides with stainless steel construction.

Price 1500 INR / Number

Minimum Order Quantity : 1 Number

Usage : Industrial

Material : Stainless Steel

Structure : Smooth

Size : Standard Sizes

ARU Series: Standard 4-row ball bearing guides with U-shaped rails.

Price 1200 INR / Number

Minimum Order Quantity : 1 Number

Usage : Industrial

Material : Stainless Steel

Structure : Smooth

Size : Standard Sizes

Send Inquiry

Send Inquiry