- Home Page

- Company Profile

-

Our Products

- CPC Linear Motion Guide

- HRU Series: High-rigidity 4-row ball bearing guides with U-shaped rails

- ERC Series: Low profile 4-row ball bearing guides

- LRR Series: Low-profile roller bearing guides

- MR Series: Miniature linear guides with stainless steel construction.

- MRU Series: Miniature linear guides with bottom-mounting options

- ARC Series: Standard 4-row ball bearing guides.

- ARU Series: Standard 4-row ball bearing guides with U-shaped rails.

- Ironless Servo Motor Linear Motion Guideway

- WRC Series 4 Row Wide Ball Type Linear Motion Guideway

- HRR 4 Row Type Linear Motion Guideway

- HRR Series Standard Roller Linear Motion Guideway

- MSS Series Linear Motion Guideway With Magnetic Encoder

- ARR 4 Roller Type Linear Motion Guideway

- 15-55 Roller Linear Motion Guideway

- HRC Series: High-rigidity 4-row ball bearing guides.

- HRR Series: High-rigidity roller bearing guides.

- ARR Series: Standard roller bearing guides.

- CPC Linear Motor

- Ironless Linear Motor

- UF - Linear Motor Stage

- Motor Servo Drive

- Sensor series

- CLS - Compact Linear Motor Stage

- CLMS - Compact Linear Motor Stage

- MMLS - Moving magnet stage

- Ironcore Linear Motor

- DD Motor

- Standard 4-Row Ball Bearing Linear Guide

- Wide 4-Row Ball Bearing Linear Guide

- Standard 4-Row Roller-type Linear Guide

- ARD Standard 4-Row Ball Bearing Linear Guide

- Miniature Linear Guide

- ST Miniature Stroke Slide Series

- Cross Roller Series

- Hiwin Linear Guide

- CPC Studio

- CPC Robot

- THK Linear Guide

- CPC Linear Motion Guide

- Contact Us

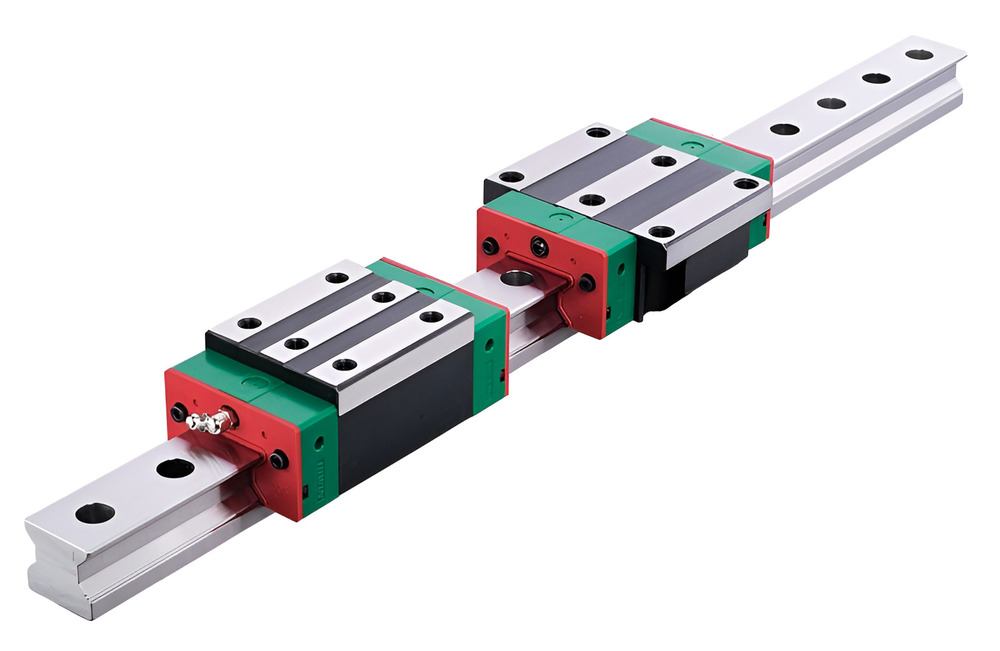

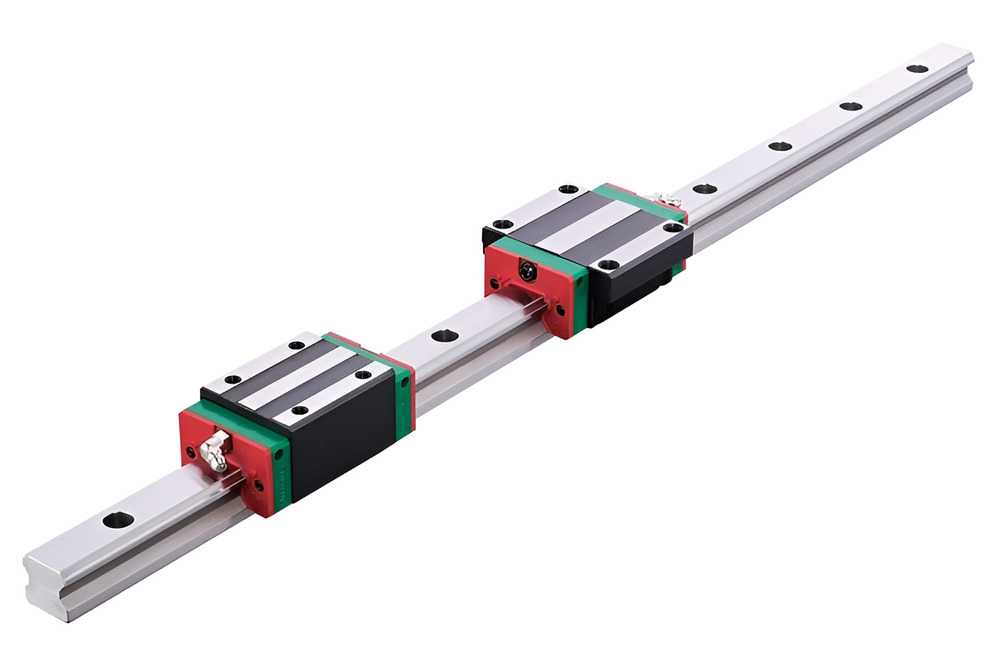

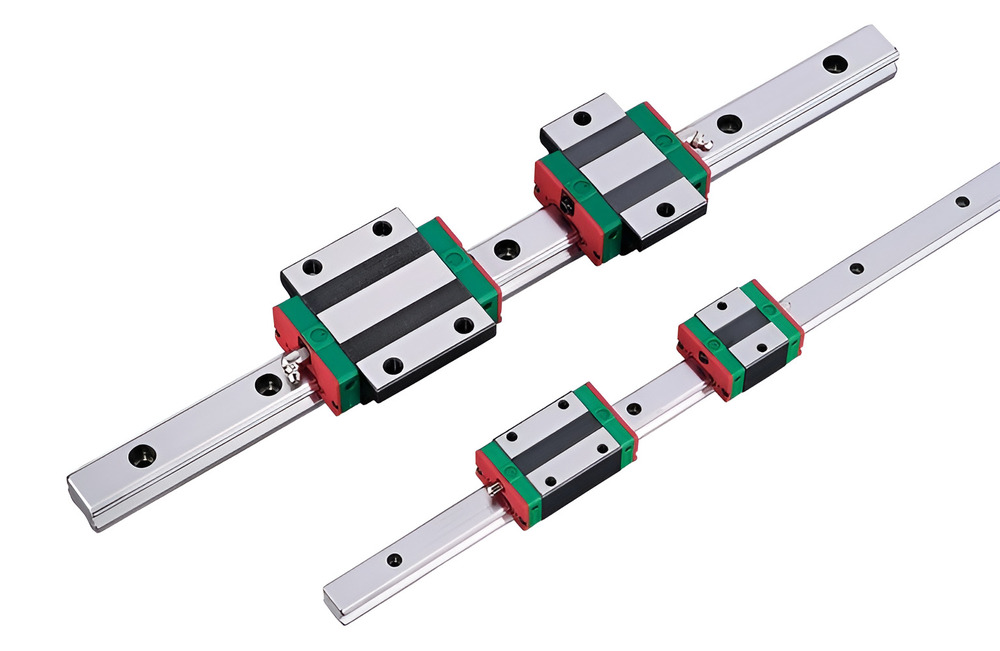

EG Series - Low-profile, self-aligning ball guideways

Price 900 INR/ Number

MOQ : 1 Piece

EG Series - Low-profile, self-aligning ball guideways Specification

- Structure

- Smooth

- Usage

- Industrial

- Material

- Stainless Steel

- Use

- Industrial

- Size

- Standard Sizes

- Warranty

- 1 YEAR

- Color

- Silver

EG Series - Low-profile, self-aligning ball guideways Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 1000 Pieces Per Month

- Delivery Time

- 7 Days

About EG Series - Low-profile, self-aligning ball guideways

Oil flooded rotary screw compressors engineered for heavy duty performance combining reliability with ease of maintenance Featuring ELG is in house eta V profile rotors these machines deliver high energy efficiency low speed operation and minimal oil carryover 1ppm thanks to the advanced OSBIC impact centrifugal separation process

Key Features

-

-

Rail & Bolt Specifications

-

Pitch (Hole Spacing): 60 mm (1525), 80 mm (3035)

-

Standard Rail Lengths: Up to 4,000 mm

-

Bolt Torque for Rail Mounting:

-

EG15: M30.5, Torque 186 N -cm (iron) / 127 N-cm (aluminum)

-

EG20: M50.8, Torque 883 / 588 N-cm

-

EG25/30: M61, Torque 1,373 / 921 N-cm

-

EG35: M81.25, Torque 3,041 / 2,010 N-cm

-

-

Precision Engineering for Industrial Reliability

EG Series ball guideways deliver smooth, accurate motion, making them ideal for demanding industrial setups. Their low-profile design and self-aligning capability minimize installation challenges and reduce maintenance, ensuring dependable performance even under continuous use.

Stainless Steel Durability

Manufactured using high-grade stainless steel, EG Series guideways offer exceptional resistance to corrosion and wear. This ensures long-lasting operation in harsh industrial environments, protecting machinery and maintaining productivity over time.

FAQs of EG Series - Low-profile, self-aligning ball guideways:

Q: How are EG Series ball guideways used in industrial automation?

A: EG Series ball guideways are integrated into industrial machinery to enable precise linear movement, enhancing the efficiency and reliability of automated systems in production lines and material handling equipment.Q: What are the benefits of using self-aligning ball guideways in industrial settings?

A: Self-aligning ball guideways compensate for installation misalignments, reducing stress on the structure and facilitating smoother motion. This results in minimized downtime and improved operational consistency.Q: When should EG Series low-profile guideways be selected for an industrial application?

A: EG Series guideways are ideal when space is limited and high-precision linear motion is required, particularly in compact machinery or automated systems demanding low maintenance and durability.Q: Where can I obtain EG Series ball guideways and related service support?

A: EG Series ball guideways are available from Taiwan-based exporters, importers, service providers, and suppliers, who can offer product selection assistance, installation guidance, and after-sales support.Q: What is the process for installing EG Series guideways in industrial equipment?

A: Installation involves mounting the guideways onto machine bases, ensuring proper alignment for optimal performance. Their self-aligning design simplifies the process and helps prevent issues related to misalignment.Q: How does stainless steel construction enhance the performance of EG Series guideways?

A: Stainless steel construction provides robust corrosion resistance and structural integrity, making EG Series guideways well-suited for environments exposed to moisture, chemicals, or heavy operational cycles.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Hiwin Linear Guide Category

RG Series -High-rigidity roller bearing guideways

Price 900 INR / Number

Minimum Order Quantity : 1 Number

Use : Industrial

Material : Stainless Steel

Structure : Smooth

Usage : Industrial

HG Series Heavy-load, high-rigidity balltype guideways

Price 900 INR / Piece

Minimum Order Quantity : 1 Piece

Use : Industrial

Material : Stainless Steel

Structure : Smooth

Usage : Industrial

MG Series Compact stainless steel miniature guides

Price 1000 INR / Number

Minimum Order Quantity : 1 Number

Use : Industrial

Material : Stainless Steel

Structure : Smooth

Usage : Industrial

Send Inquiry

Send Inquiry