- Home Page

- Company Profile

-

Our Products

- CPC Linear Motion Guide

- HRU Series: High-rigidity 4-row ball bearing guides with U-shaped rails

- ERC Series: Low profile 4-row ball bearing guides

- LRR Series: Low-profile roller bearing guides

- MR Series: Miniature linear guides with stainless steel construction.

- MRU Series: Miniature linear guides with bottom-mounting options

- ARC Series: Standard 4-row ball bearing guides.

- ARU Series: Standard 4-row ball bearing guides with U-shaped rails.

- Ironless Servo Motor Linear Motion Guideway

- WRC Series 4 Row Wide Ball Type Linear Motion Guideway

- HRR 4 Row Type Linear Motion Guideway

- HRR Series Standard Roller Linear Motion Guideway

- MSS Series Linear Motion Guideway With Magnetic Encoder

- ARR 4 Roller Type Linear Motion Guideway

- 15-55 Roller Linear Motion Guideway

- HRC Series: High-rigidity 4-row ball bearing guides.

- HRR Series: High-rigidity roller bearing guides.

- ARR Series: Standard roller bearing guides.

- CPC Linear Motor

- Ironless Linear Motor

- UF - Linear Motor Stage

- Motor Servo Drive

- Sensor series

- CLS - Compact Linear Motor Stage

- CLMS - Compact Linear Motor Stage

- MMLS - Moving magnet stage

- Ironcore Linear Motor

- DD Motor

- Standard 4-Row Ball Bearing Linear Guide

- Wide 4-Row Ball Bearing Linear Guide

- Standard 4-Row Roller-type Linear Guide

- ARD Standard 4-Row Ball Bearing Linear Guide

- Miniature Linear Guide

- ST Miniature Stroke Slide Series

- Cross Roller Series

- Hiwin Linear Guide

- CPC Studio

- CPC Robot

- THK Linear Guide

- CPC Linear Motion Guide

- Contact Us

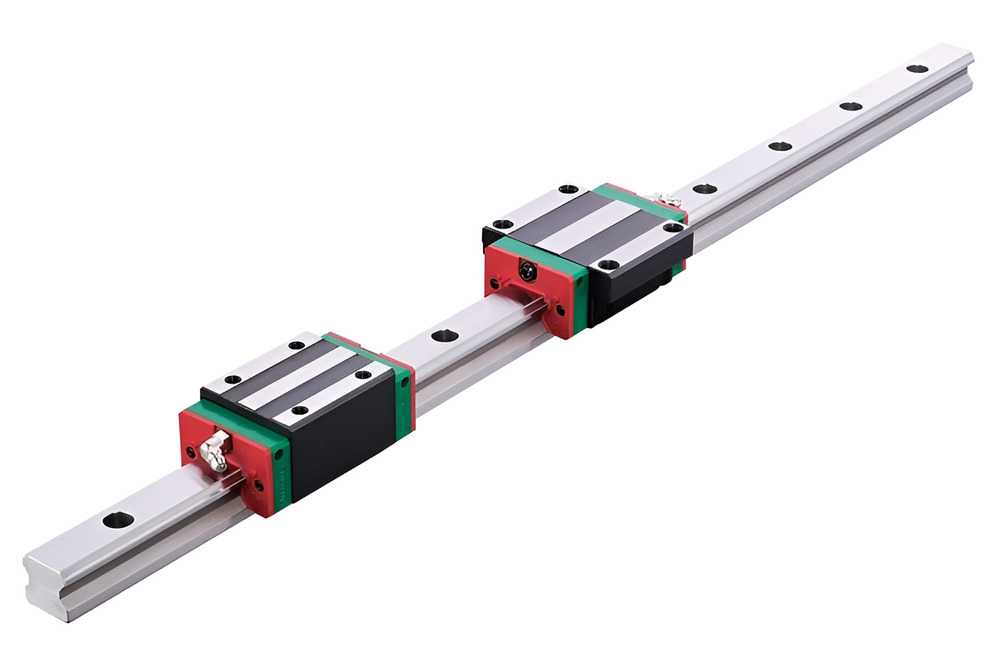

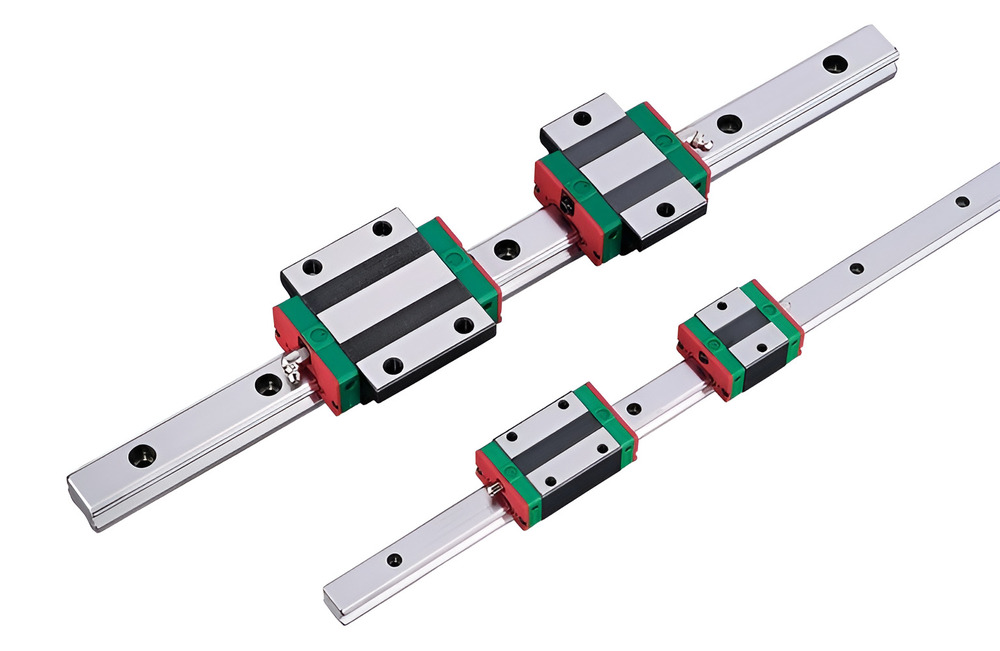

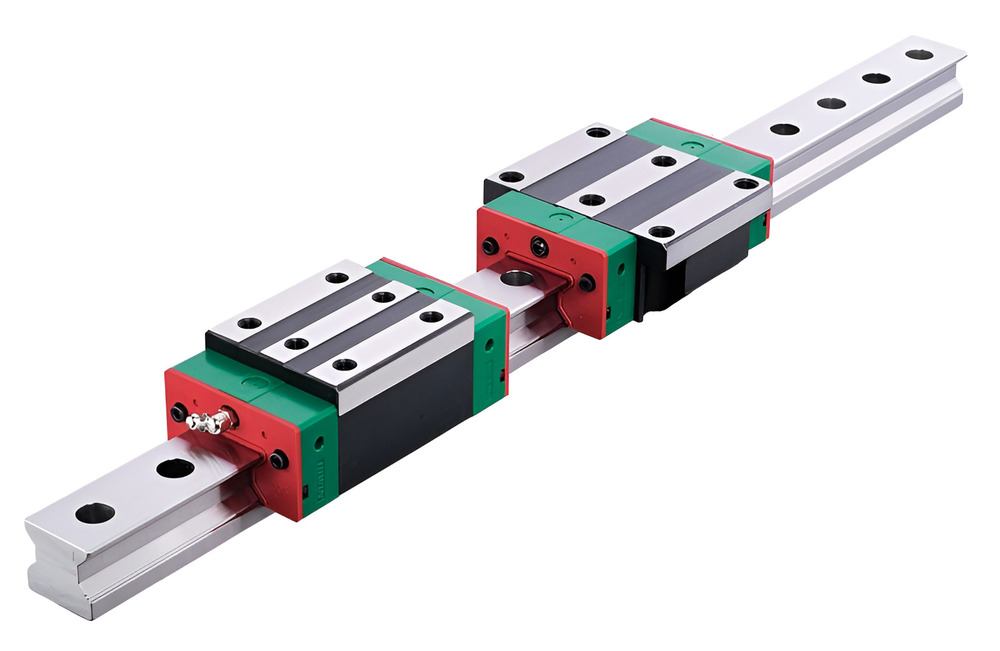

RG Series -High-rigidity roller bearing guideways

Price 900 INR/ Number

MOQ : 1 Number

RG Series -High-rigidity roller bearing guideways Specification

- Structure

- Smooth

- Usage

- Industrial

- Material

- Stainless Steel

- Use

- Industrial

- Size

- Standard Sizes

- Warranty

- 1 YEAR

- Color

- Silver

RG Series -High-rigidity roller bearing guideways Trade Information

- Minimum Order Quantity

- 1 Number

- Supply Ability

- 1000 Per Month

- Delivery Time

- 7 Days

About RG Series -High-rigidity roller bearing guideways

The RG Series replaces classic steel ball elements with rollers providing superhigh rigidity and exceptional load capacity in all four directions radial reverse radial lateral vertical This is thanks to its 45 contact angle and roller to rail contact design which significantly reduces elastic deformation under heavy loads

With radial rigidity up to 5412Nm and a static load capacity reaching 572kN the RG Series is engineered for demanding precision applications and longer service life in high performance environments

Uses cylindrical rollers instead of balls, increasing contact area and rigidity.

-

Features a 45 four-row roller configuration for uniform load capacity in all directions (radial, reverse-radial, lateral).

-

Designed for super high rigidity and load capacity, minimizing elastic deformation.

-

Roller-to-rail line contact reduces stress concentration and extends service life.

-

Available in flange and square block types; flange blocks provide low height and better moment resistance.

-

Rails offered in top-mount and optional bottom-mount types.

-

Superior Durability and Performance

Crafted from high-grade stainless steel, the RG Series roller bearing guideways offer exceptional resistance to wear and corrosion. Their high-rigidity design supports stable and precise movement in industrial machinery, resulting in reduced maintenance and enhanced reliability. These guideways provide consistent performance under heavy loads and in challenging environments.

Versatile Industrial Applications

The RG Series guideways are suitable for a wide range of industrial uses, including automation equipment, CNC machinery, and production lines. Their adaptability makes them a preferred solution for exporters, importers, service providers, and suppliers seeking reliable, smooth linear motion components sourced from Taiwan.

FAQs of RG Series -High-rigidity roller bearing guideways:

Q: How are RG Series roller bearing guideways installed in industrial machinery?

A: RG Series guideways are compatible with standard mounting configurations and should be securely fastened using appropriate fixtures. Installation instructions provided by the supplier should be followed to ensure proper alignment and optimal performance.Q: What benefits do stainless steel roller bearing guideways provide over conventional options?

A: Stainless steel offers superior resistance to corrosion, wear, and harsh industrial conditions. This translates to longer product lifespan, reduced maintenance, and increased reliability compared to conventional materials.Q: When should the RG Series guideways be serviced or replaced?

A: Under regular usage, the guideways generally require minimal maintenance. It is recommended to inspect them periodically during machinery routine checks, and consider replacement if signs of excessive wear, damage, or performance decline are observed within or after the warranty period.Q: Where can the RG Series guideways be sourced from?

A: These guideways are available through exporters, importers, service providers, and suppliers based in Taiwan who specialize in high-quality industrial components.Q: What is the process for claiming warranty support for RG Series guideways?

A: If a product issue arises within the one-year warranty period, customers should contact the supplier directly, providing purchase details and evidence of the problem. The supplier will guide you through the troubleshooting and replacement process based on warranty terms.Q: How are RG Series guideways typically used in industrial settings?

A: They are employed to enable smooth and stable linear motion in equipment such as CNC machines, automation systems, and other machinery requiring precise guidance, ensuring both performance and reliability.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Hiwin Linear Guide Category

HG Series Heavy-load, high-rigidity balltype guideways

Price 900 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Stainless Steel

Warranty : 1 YEAR

Color : Silver

Usage : Industrial

EG Series - Low-profile, self-aligning ball guideways

Price 900 INR / Number

Minimum Order Quantity : 1 Piece

Material : Stainless Steel

Warranty : 1 YEAR

Color : Silver

Usage : Industrial

MG Series Compact stainless steel miniature guides

Price 1000 INR / Number

Minimum Order Quantity : 1 Number

Material : Stainless Steel

Warranty : 1 YEAR

Color : Silver

Usage : Industrial

Send Inquiry

Send Inquiry