Price 1000 आईएनआर/ Number

MOQ : 1 Number

Specification

- स्ट्रक्चर

- Smooth

- उपयोग

- Industrial

- मटेरियल

- उपयोग करें

- Industrial

- साइज

- Standard Sizes

- वारंटी

- 1 YEAR

- रंग

- Silver

Trade Information

- Minimum Order Quantity

- 1 Number

- आपूर्ति की क्षमता

- प्रति महीने

- डिलीवरी का समय

- दिन

About

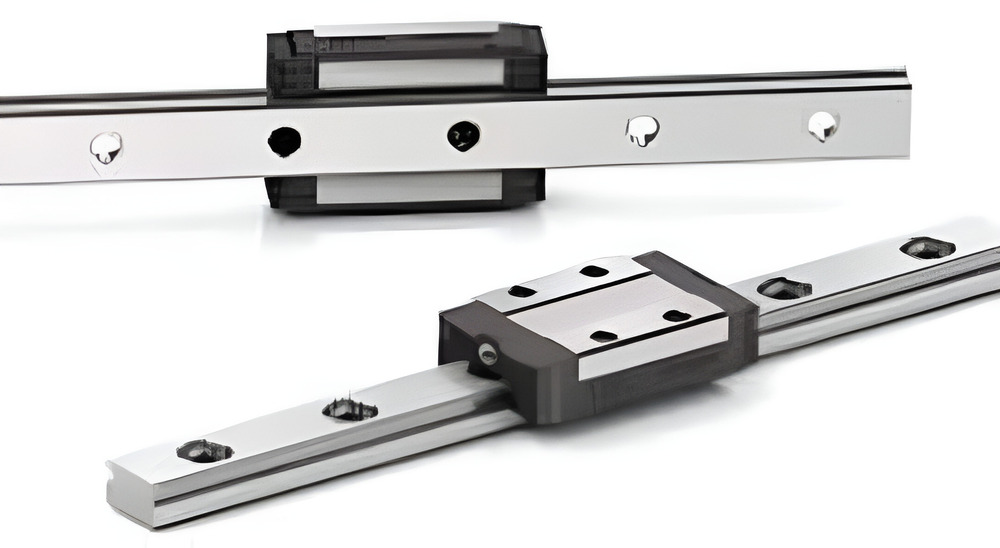

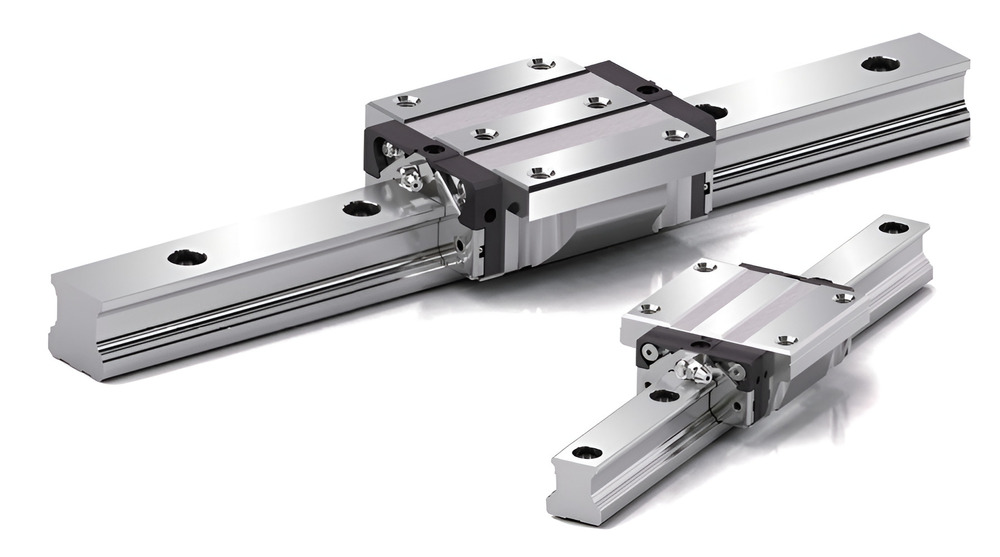

The LRR Series offers high precision low profile linear guides designed for applications demanding exceptional rigidity accuracy and smooth motion in a compact format Utilizing advanced roller bearing technology these guides provide greater load capacity and reduced deflection compared to conventional ball bearing systems The low profile design makes them ideal for space constrained installations while their robust construction ensures long term performance with minimal maintenance Engineered for reliability and precision the LRR Series is a trusted solution in automation medical devices semiconductor equipment and high performance machinery

Advantage

- Compact design fits tight spaces

-

- High loadbearing and moment resisting capacity

-

- Excellent for highspeed high precision applications

-

- Long service life with minimal maintenance

-

- Low deflection under load

-

Sizes: 1545 mm

-

Load Capacities: 11.392.6 KN dynamic

-

Static Loads: Up to 61.5 KN

-

Roller-Type Design: High rigidity and load capacity

-

Rails: Up to 4 m with 60/80 mm pitch

Efficient Motion for Industrial Use

Engineered specifically for industrial environments, the LRR Series ensures seamless movement in automated machinery and assembly lines. The robust stainless steel construction allows for long-lasting performance, even under continuous operation.

Corrosion-Resistant Build

Made entirely from stainless steel, these roller bearing guides boast excellent resistance to rust and wear. The smooth surface ensures optimal motion while reducing maintenance needs, providing reliability in diverse working conditions.

Reliable Taiwanese Quality

As a leading exporter, importer, service provider, and supplier from Taiwan, we maintain strict quality control standards. The LRR Series exemplifies our commitment to delivering high-grade, durable solutions for industrial clients worldwide.

FAQs of LRR Series: Low-profile roller bearing guides:

Q: How are LRR Series roller bearing guides typically used in industrial settings?

A: LRR Series roller bearing guides are commonly incorporated into automated equipment, conveyor systems, and industrial machinery to facilitate precise, smooth linear motion, reducing friction and wear.Q: What benefits do stainless steel LRR Series guides provide for industrial applications?

A: The stainless steel material ensures resistance to corrosion, robust durability, and reduced maintenance, making these guides suitable for harsh industrial environments where resilience is critical.Q: When should roller bearing guides in the LRR Series be replaced or serviced?

A: It is recommended to inspect the guides periodically during routine equipment maintenance. Replacement or servicing may be required if abnormal noise, wear, or reduced motion accuracy is observed over time.Q: Where are the LRR Series guides sourced and distributed from?

A: These guides are exported and supplied by professional service providers, importers, and suppliers based in Taiwan, ensuring adherence to strict manufacturing and quality standards.Q: What is the installation process for LRR Series roller bearing guides?

A: Installation involves securing the guides in designated tracks or mounts within machinery. Detailed instructions are provided to ensure accurate alignment for optimal performance and durability.Q: How does the smooth structure of the LRR Series enhance operational efficiency?

A: The smooth structure reduces contact friction and vibration during operation, allowing for more precise movement, quieter performance, and extended equipment lifespan.Q: What warranty coverage is available for the LRR Series?

A: The LRR Series roller bearing guides are covered by a 1-year warranty, which protects against manufacturing defects and provides assurance of reliable operation for industrial users.

Tell us about your requirement

Price: Â

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

मोबाइल number

Email

अधिक Products in लीनियर मोशन गाइडवे Category

ARR 4 रोलर टाइप लीनियर मोशन गाइडवे

माप की इकाई : यूनिट/यूनिट

मूल्य की इकाई : यूनिट/यूनिट

उपयोग : औद्योगिक

साइज : भिन्न उपलब्ध

न्यूनतम आदेश मात्रा : 10

मटेरियल : स्टेनलेस स्टील

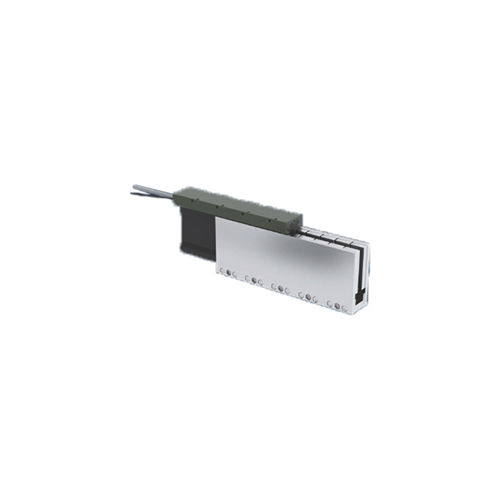

आयरनलेस सर्वो मोटर लीनियर मोशन गाइडवे

माप की इकाई : यूनिट/यूनिट

मूल्य की इकाई : यूनिट/यूनिट

उपयोग : औद्योगिक

साइज : भिन्न उपलब्ध

न्यूनतम आदेश मात्रा : 10

मटेरियल : स्टेनलेस स्टील

जांच भेजें

जांच भेजें